ZnSe is used to form II-VI light-emitting diodes and diode lasers. It emits blue light. It is susceptible to n-type doping with, for instance, halogen elements. P-type doping is more difficult, but can be achieved by introducing nitrogen.

ZnSe doped with chromium (ZnSe:Cr) has been used as an infrared laser gain medium emitting at about 2.5 µm.

It is used as an infrared optical material with a remarkably wide transmission wavelength range (0.45 µm to 21.5 µm[2]). The refractive index is about 2.67 at 550 nm (green), and about 2.40 at 10.6 µm (LWIR). Similar to zinc sulfide, ZnSe is produced as microcrystalline sheets by synthesis from hydrogen selenide gas and zinc vapour. Lasertran (trademark of Rohm & Haas) grade is especially free of absorption and inclusions and is used particularly for CO2 laser optics at 10.6 µm wavelength. It is thus a very important IR material. In daily life, it can be found as the entrance optic in the new range of "in-ear" clinical thermometers and can be just seen as a small yellow window. Zinc selenide can slowly react with atmospheric moisture if poorly polished, but this is not generally a serious problem. Except where optics are use in spectroscopy or at the brewster angle, antireflection or beamsplitting optical coatings are generally employed.

ZnSe activated with tellurium (ZnSe(Te)) is a scintillator with emission peak at 640 nm, suitable for matching with photodiodes. It is used in x-ray and gamma ray detectors. ZnSe scintillators are significantly different from the ZnS ones.

Zinc selenide is a clear yellow polycrystalline material with a grain size of approximately 70µm, transmitting in the range 0.5-15µm. It is essentially free of extrinsic impurity absorptions, providing extremely low bulk losses from scatter. The main identifiable extrinsic bulk absorption is zinc hydride, whose free diatomic molecule has a vibrational mode at 1608cm-1. Having a very low absorption of energy makes it useful for optical components in high power laser window and multispectral applications, providing good imaging characteristics. ZnSe is also useful in high resolution thermal imaging systems, where it is used to correct for colour distortion which is often inherent in other lenses used in the system. An observed electronic absorption edge at approximately 0.476µm (~ 2.6eV) at 300K and far infrared multi-phonon absorption edge commencing at approximately 22.2µm.

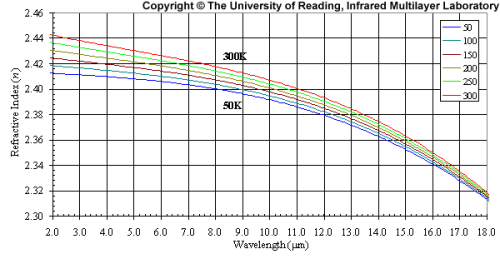

Dispersion

The multi-phonon lattice absorption of ZnSe has been extensively investigated since the first transmission and reflection measurements were made by Aven et al on cubic ZnSe in 1961. Since neutron-scattering and Raman-scattering have become available in the early 1970's, as has the increased availability of CVD ZnSe, investigations of ZnSe has demonstrated that in the three and four-phonon regions, ZnSe exhibits a characteristic structure consistent with predicted calculations by Bendow et al.

At wavelengths between the visible and infrared regions, ZnSe behaves as a dielectric material, with a refractive index decreasing with increasing wavelength. The mean value of n being approximately 2.4 at 300K. Over this same region, the extinction coefficient k is very small (<10-5), providing uniformly high transmission. As a result of these characteristics, ZnSe has been used extensively for optical components and windows. Marple et al derived the following Sellmeier type dispersion equation at 300K with a claimed experimental error of ± 0.002 ;

The effects of temperature on this refractive index profile was investigated across a narrow temperature range (243-343K) by Barron using a Buchdahl refractive index polynomial.

Zinc Selenide (ZnSe) - transparent in wide spectral range from yellow (visible) to far IR. ZnSe material is a chemically inert, non-hygroscopic and highly pure product that is very effective in many optical applications due to its extremely low bulk losses, high resistance to thermal shock and stability in virtually all environments, easily machined. To obtain superior transmittance, ZnSe crystals are grown by Chemical Vapor Deposition process (CVD). Zinc Selenide CVD is polycrystalline material, demonstrates superior CO2 laser transmittance and is employed in the transmission optical components used in CO2 laser processing.

ZnSe (Zinc Selenide) Chemical Vapor Deposition (CVD) material is produced by synthesis from zinc vapour and H2Se gas, forming as sheets on graphite susceptors (ZnSe-CVD processes). Chemical purity of CVD-ZnSe 99.999%. It has à polycrystalline structure; the grain size of Zinc Selenide CVD material is controlled to produce maximum strength.

The transmission range of Zinc Selenide ZnSe-CVD is (0.5 – 20) microns. ZnSe CVD used for high power CO2 laser optics at 10.6 microns, for protective optics windows or optical elements in FLIR (forward looking infrared) thermal imaging equipment, optics for medical and industrial applications (optical plane parallel windows (plates, disks, sheets, slabs, blanks), wedged windows, Brewster windows, optical meniscus, spherical and cylindrical lenses, prisms, resonator mirrors of CO2 laser).

Single crystal ZnSe Zinc Selenide is available, but is not common, it has lower bulk losses and thus more effective for CO2 optics.

Crystaltechno Ltd.

grows Zinc Selenide (ZnSe) CVD ingots with size up to 270 mm x 500 mm, thickness up to 20mm, transparent during the spectral range (0.5 -20) microns.

manufactures from Zinc Selenide ZnSe CVD the following optics blanks, windows, protective windows, wedges, cylindrical and spherical lenses, meniscus, right angle prisms, ATR prisms, CO2 optics, resonator mirrors for CO2 laser at 10.6 microns, Brewster windows, domes, spherical microlenses, balls and hemisphere, ZnSe witness samples. These products are particularly for infrared applications including CO2 laser optics.

offers Evaporation Grade Zinc Selenide ZnSe-CVD (size less than or equal to 6 mm, purity: 99.999%)

Nenhum comentário:

Postar um comentário